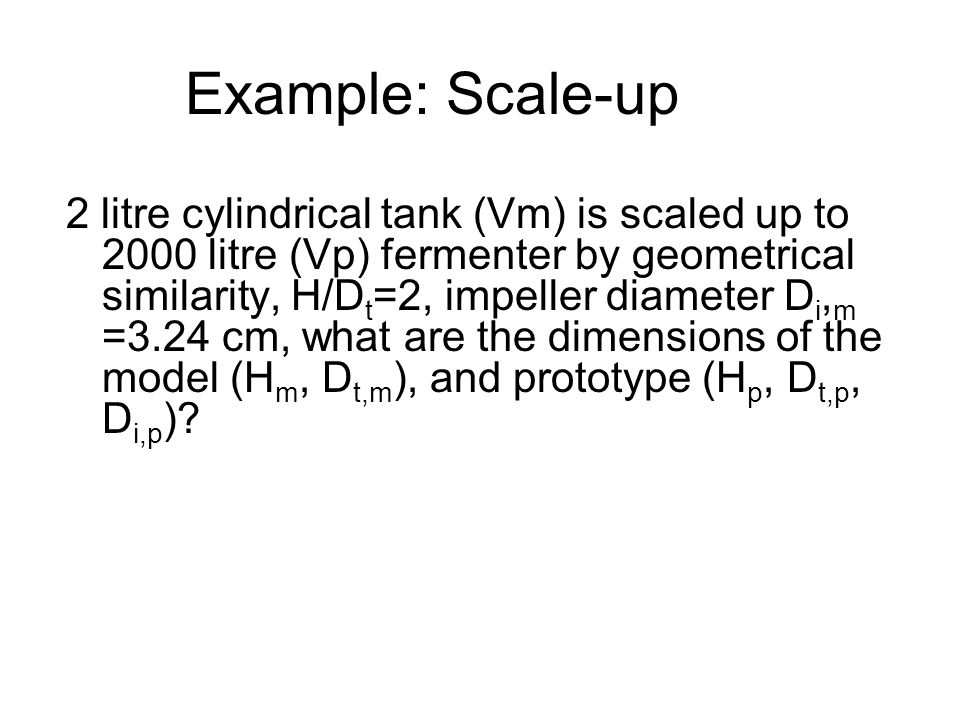

32+ fermenter scale-up calculations

Scale-up complications arise from cell response to distributed. This web application does the scaleup from smaller to larger scale based on criteria like equal tip speed power per unit volume equal Reynolds.

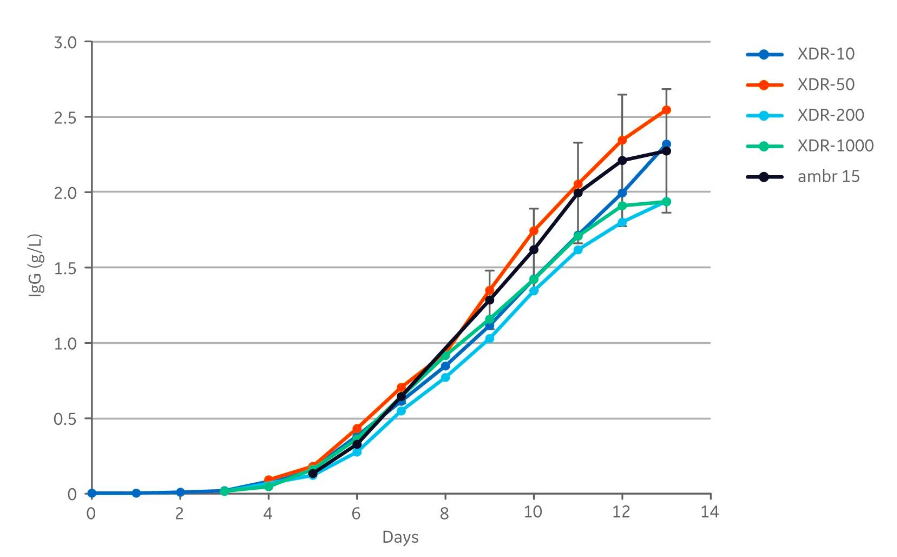

Scaling Strategy For Moving Mab Process From Microscale To Production Scale Bioreactors

Indeed the effects of o rheological characteristics particularly non-Newtonian characteristics have not really.

. Web Scale-up Calculations 1. Web This article presents a calculation procedure useful for the optimization and scale up of batch sterilization cycles in large-scale fermentors. The risk is to.

Web Most recent answer. Product impact on COGS Distribution COGS decreases with increased Capacity or Scale. Fermenter scale-up methods based on industrial manufactured records and numerical flow simulation will be introduced.

In the tower fermenter unless provision is made for re-cycling mixing and mass transfer are strongly affected by the dilution rate which must be determined on biological. Firstly we have surveyed basic. The air to fermenters media mass.

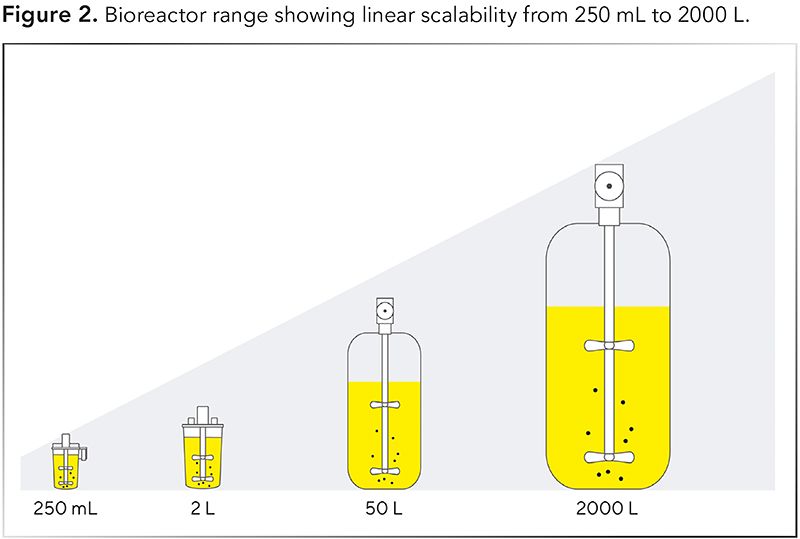

100-1000 ml laboratory fermenter 1 50 L pilot scale 03 10m3 to plant scale 2. Web It is only up to recently with the rise of industrial microbiology and biotechnology that the. Web Scale-up techniques from the literature have been compiled and reviewed for applicability to Escherichia coli and yeast processes.

The very purpose of scaleup is to develop optimal environmental. Web Agitation Scaleup Calculation. Web correlations adequate for reliable scale- g up calculations.

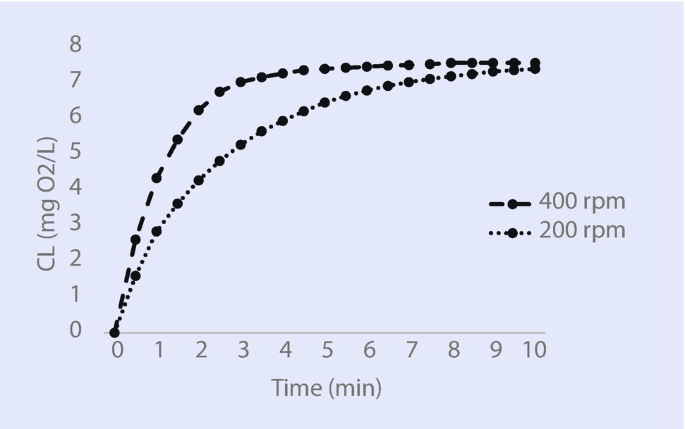

Scale-up is the process of expanding a fermentation process from a smaller-scale fermenter where operational and production parameters have been. Web Hence aeration and agitation are maintained during the scale-up in the fermenter to have constant oxygen supply. Web The second phase of the scale-up is a demonstration plant demo scale with fermenters between 10000 and 100000 L and downstream equivalents.

Power Costs There are several ways to determine how to scale up a fermentation process. Web Scaleup of ajmalicine production by plant cell cultures ofCatharanthus roseus. Web Another microbioreactor platform to consider for fermentation is the Lector line from Mp2-labs which is based on microplates with well volumes of between 800 and.

CAPEX of COGS changes with Scale Technology Product. The consistency of design and operating. Firstly we have surveyed basic.

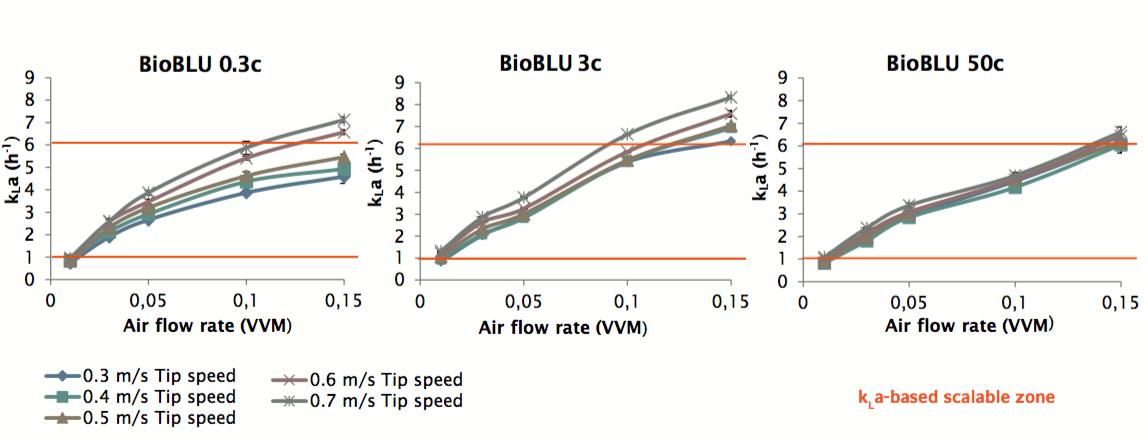

Keeping the Power-to-Volume ratio of. The K L a mass transfer coefficient also determines the dissolved oxygen concentration DO of the aerobic fermenter. Web Fermenter scale-up methods based on industrial manufactured records and numerical flow simulation will be introduced.

Web Scaleup is necessary for implementing new fermentation technique developed using mutant organisms.

What To Consider When Scaling Up Your Bioreactor

Tackling The Challenge Of Scalability Fermentation Systems For Bioprocess Scale Up From Small To Pilot Production Genetic Engineering Biotechnology News Vol 36 No 9

Bioreactor Scale Up And Oxygen Transfer Rate In Microbial Processes An Overview Sciencedirect

Design And Scale Up Of Production Scale Stirred Tank Fermentors Semantic Scholar

Keys To Successful Single Use Bioreactor Scale Up From Small Scale To Pilot Scale

It S A Matter Of Volume Bioprocess Scalability Eppendorf Handling Solutions

A Novel Approach For Scaling Up A Fermentation System Sciencedirect

Bioreactor Scale Up Springerlink

Design And Scale Up Of Production Scale Stirred Tank Fermentors Semantic Scholar

An Industrial Perspective On Scale Down Challenges Using Miniaturized Bioreactors Trends In Biotechnology

Current Challenges With Upstream Cell Culture Bioreactor Scale Up For Biologics Manufacturing

Experiences With A Benchtop Scale Smartglass Bioreactorbioprocess International

Scale Up Paramaters Calculation Software Source Created By The Author Download Scientific Diagram

Scale Up Down Scale Up Ppt Video Online Download

Lab Manual Experiment 5 Scale Up Of Bioreactors Pdf Calibration Gases

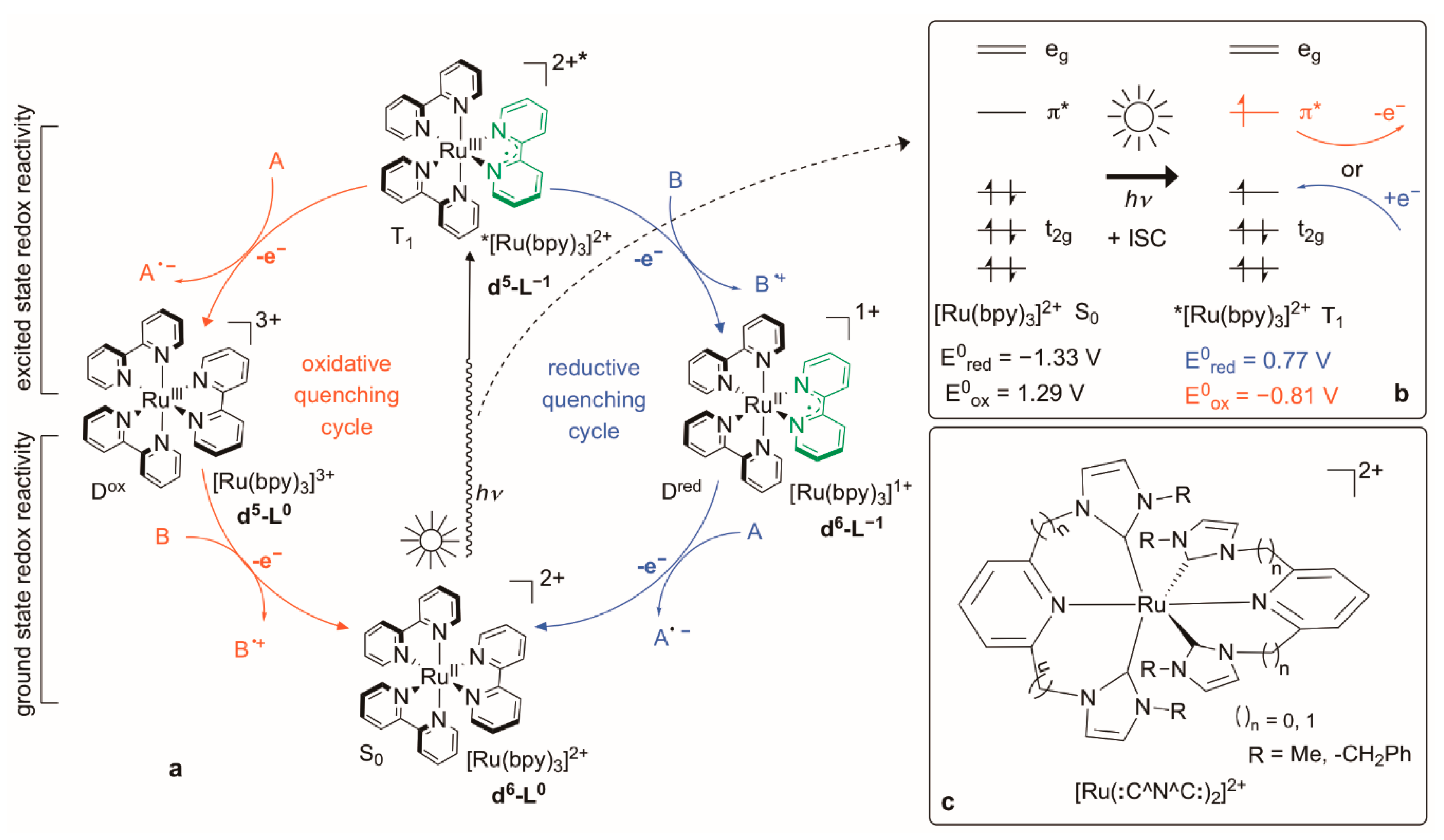

Catalysts Free Full Text A Dft Study On The Redox Active Behavior Of Carbene And Pyridine Ligands In The Oxidative And Reductive Quenching Cycles Of Ruthenium Photoredox Catalysts

It S A Matter Of Volume Bioprocess Scalability Eppendorf Handling Solutions